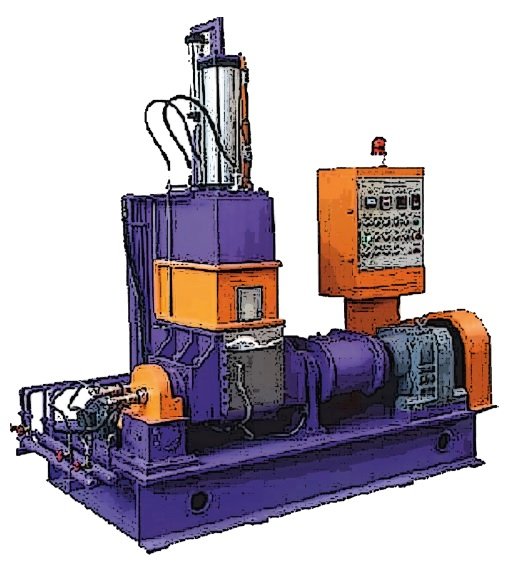

RUBBER DISPERSION KNEADER

RUBBER DISPERSION KNEADER

Rubber Dispersion Kneader machine ensures homogeneous compound dispersion, easy colour change cleaning, and simple operation, and represents technoeconomic achievement. Dispersion Kneader may be used to combine a wide range of materials, from low viscosity adhesives to high viscosity rubber.

Rubber Dispersion Kneader produces emulsions of two immiscible liquids or dispersions of solid particles in a liquid medium. The mixers generally operate on the rotor/mastication principle and apply a high shear force on the suspended particles to break them down.

Expectations

- Great in Production.

- A perfect Dispersion with homogeneous & hygienic mixing of Ingredients.

- Avoid losses of expensive ingredients from Leakages.

- Avoid batch-to-batch inconsistency.

- A dust-free mixing.

- An energy efficient model.

- User Friendly machine

- Low in Maintenance.

- A heavy duty and sturdy.

OPTIONAL ADVANCED TECHNOLOGY

- Touch Screen with PLC Controlling & Operating.*

- Data Backup, Online Supervision, SCADA Ect.*

- Advance Backup on your Android or IOS.**

- Advanced Recipe Storage with Fully Automation.*

- Batch Consistency Quality and Fast Dispersion.

- Variable Frequency Drive “VFD” Operated.*

- Hydraulically Operated Top Lid and Tilting system.

- Advanced Temperature Controlling System.*

- Automatic Carbon Feeding Injector.*

- Energy Efficient Models.

- High Performance Stellite welding with Certificate.

- Stainless Steel Rotors and Chamber.*

- Highest & Advanced Safety Standards Interlocks.