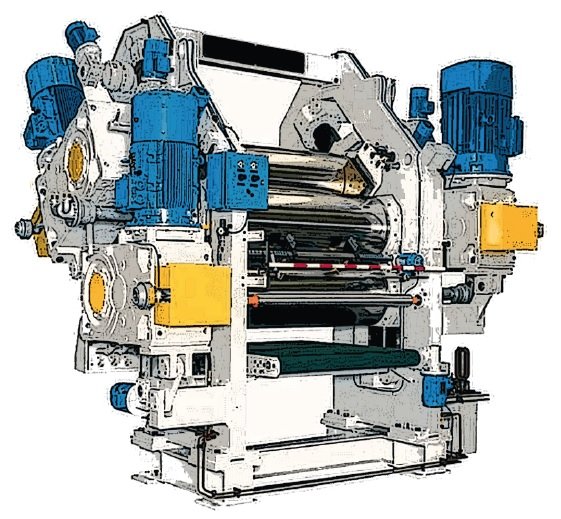

RUBBER CALENDER MACHINE

RUBBER CALENDER MACHINE

Heavy Duty - Type

A high precise calendering machine with 2, 3, 4 Rolls for Sheeting, Fabric Coating, Cushion Gum, with suitable lines etc.

- 2 Roll Calender Horizontal Type

- 2 Roll Calender Vertical Type

- 2 Roll Calender Inclined or Tilted Type

- 3 Roll Calender Vertical Stack Type

- 3 Roll Calender Offset Stack

- 4 Roll Calender Vertical Type

- 4 Roll Calender Inverted ‘L’ Type

- 4 Roll Calender Stack ‘S’ Type

- 4 Roll Calender Stack Open ‘Z’ Type

A complete sturdy model with Anti Friction Roller Bearing type.

Roller Bearing from SKF / ZKL or STD make.

Chilled Cast Iron Rolls with Surface Hardness 520 to 540 BHN with a suitable Friction ratio.

An optimum uniform Sheet thickness with minimum tolerance.

Effective water heating / cooling circulation system with Leakproof solution.

Automatic lubrication system with interlock.

Helical reputed make gearbox with highest safety factor.

Energy efficient Motor / drive.

A complete and advanced Safety feature for Machine-to-Human and machine-tomachine. eg Safety Chest Bar, Paddle, safety operating Cage, Rope, light curtains, etc.

Best In class electrical panel with branded ingredients

Key Features

- All Brought out components are From Reputed Brands.

- Necessary Test Certificates Provided for “Metallurgy and manufacturing Process”.

- Heavy-Duty and Sturdy Models with “Advance Technology”.

- A complete Safety parameters with Trustworthy Models.

OPTIONAL ADVANCED TECHNOLOGY

- Touch Screen with PLC Controlling & Operating.

- Data Backup, Online Supervision, SCADA Ect.

- Automatic Feeding System.

- Sheet Thickness Variation Monitoring.

- Zero Play clearance Device.

- Variable Frequency Drive “VFD” Operated.

- Special Roll attachment provided for Sheeting.

- Automatic Strip Cutting Mechanism.

- Edge Cutting and Auto Feeding.

- Energy Efficient Models.

- Stainless Steel Stock Tray.

- Highest & Advanced Safety Standards Interlocks.

- Advanced Temperature Controlling System.

- Digital Nip Gap and Temperature Indicator.

- Fast & Effective Cooling System Additional.

- Hydraulically Operated Stock Guide/Pusher.

- Wireless Temp Monitoring & Controlling System.

- Motorised Nip Gap Adjustments.