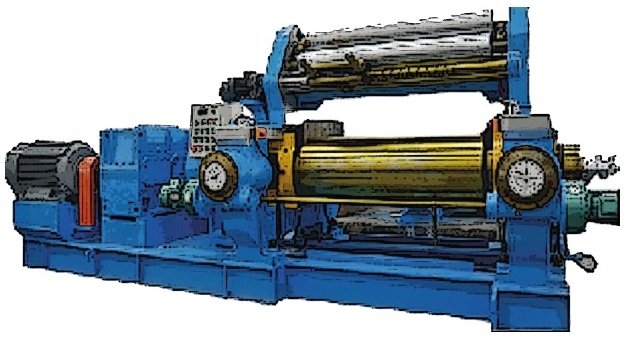

MIXING MILL WITH STOCK BLENDER

Compounding / Mixing / Sheeting / Striping / Warming

MIXING MILL WITH STOCK BLENDER

Heavy Duty - Type

Two Roll Rubber Mixing Mill Uni Drive Type

The two roll rubber mill is a machine used to process rubber into various compounds.

Two horizontally opposed Chilled cast Iron rolls rotate in opposite directions towards each other at different speeds to mix the rubber and ingredients used to create the various rubber compounds.

Rubber compounding / mixing / sheeting: incorporating rubber ingredients into a rubber mixture so it is evenly dispersed, then the rubber mixture is called a rubber compound.

The mill helps in two main steps of rubber processing – mastication and mixing.

And turned that compound into sheet form which is thoroughly event in width.

A complete sturdy model with Anti Friction Roller Bearing type

Roller Bearing from STD make

Chilled Cast Iron Rolls with Surface Hardness 520 to 540 BHN with suitable Friction ratio eg. 1:1.08 / 1:1.10 / 1:1.12 etc.

Effective water cooling circulation system with Leakproof solution.

Automatic lubrication system with interlock.

Helical reputed make gearbox with highest safety factor

Energy efficient Motor / drive.

A complete and advanced Safety feature for Machine-to-Human and machine-tomachine. eg Safety Chest Bar, Paddle, safety operating Cage, Rope, light curtains etc.

Best In class electrical panel with branded ingredients

Key Features

- All Brought out components are From Reputed Brands.

- Necessary Test Certificates Provided for “Metallurgy and manufacturing Process”.

- Heavy-Duty and Sturdy Models with “Advance Technology”.

- A complete Safety parameters with Trustworthy Models.

OPTIONAL ADVANCED TECHNOLOGY

- Touch Screen with PLC Controlling & Operating.

- Data Backup, Online Supervision, SCADA Ect.

- Automatic Feeding System.

- Advance Backup on your Android or IOS.

- Advanced Recipe Storage with Fully Automation.

- Variable Frequency Drive “VFD” Operated.

- Automatic Strip Cutting Mechanism.

- Energy Efficient Models.

- Stainless Steel Stock Tray.

- Highest & Advanced Safety Standards Interlocks.

- Advanced Temperature Controlling System.

- Digital Nip Gap and Temperature Indicator.

- Fast & Effective Cooling System Additional.

- Hydraulically Operated Stock Guide/Pusher.

- Hydraulically Operated Stock Blender Bar.

- Wireless Temp Monitoring & Controlling System.

- Hydraulically / Motorised Nip Gap Adjustments.